NPI Lean

Lean in New Product Introduction (NPI Lean)

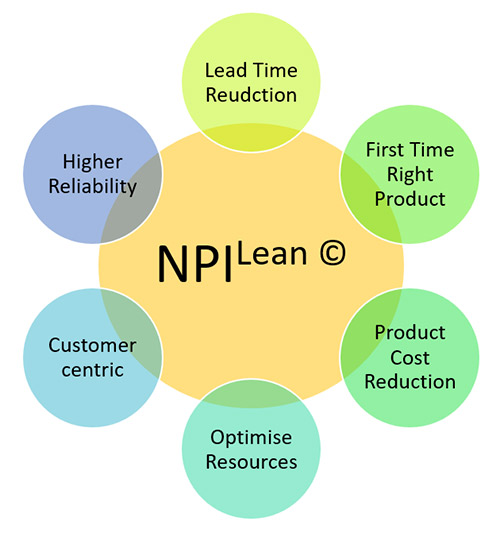

NPILean © identifies the wastes and eliminates them to achieve shorter lead time and manufactures First-Time-Right (FTR) products at optimum costs, thus re-engineering the NPI System. The principles of Lean are applied for studying the inbound and out bound logistics of any manufacturing model to achieve the Lean objectives. An NPI Process is also a value chain, which converts the customer requirements into a tangible new product; It starts from the organization structure, goes through customer’s requirements and ends with customer satisfaction; virtually covering the NPD system of concept generation, creation, distribution and after sales network.

What We Do:

How Client is benefited:

- Optimize the organizational structure and plant location

- Select suitable vendors and their location

- Identify the customer requirement and convert them into design elements of the product to optimize it

- Identify the waste processes during product development phase and eliminate them by implementing the Lean principles

- Optimize the component count at the design stage itself

- Optimize the assembly costs and the tolerancing of new products even before the detail designs are taken

Past Program Testimonials

I had basic awareness of DFMA, but now I think I got adequate information which will help me to exceed/accelerate my work.

Nithin MahaleDFMA Emerson Design Centre

I had basic awareness of DFMA, but now I think I got adequate information which will help me to exceed/accelerate my work.

Nithin MahaleDFMA Emerson Design Centre

I had basic awareness of DFMA, but now I think I got adequate information which will help me to exceed/accelerate my work.

Nithin MahaleDFMA Emerson Design Centre

Contact With our Expert

This program can be further customized after understanding your requirements. Write to us by clicking the button below and we would be happy to tailor a course as per your industry needs.

I am Interested!