Product Cost Reduction - Case Study

Situation

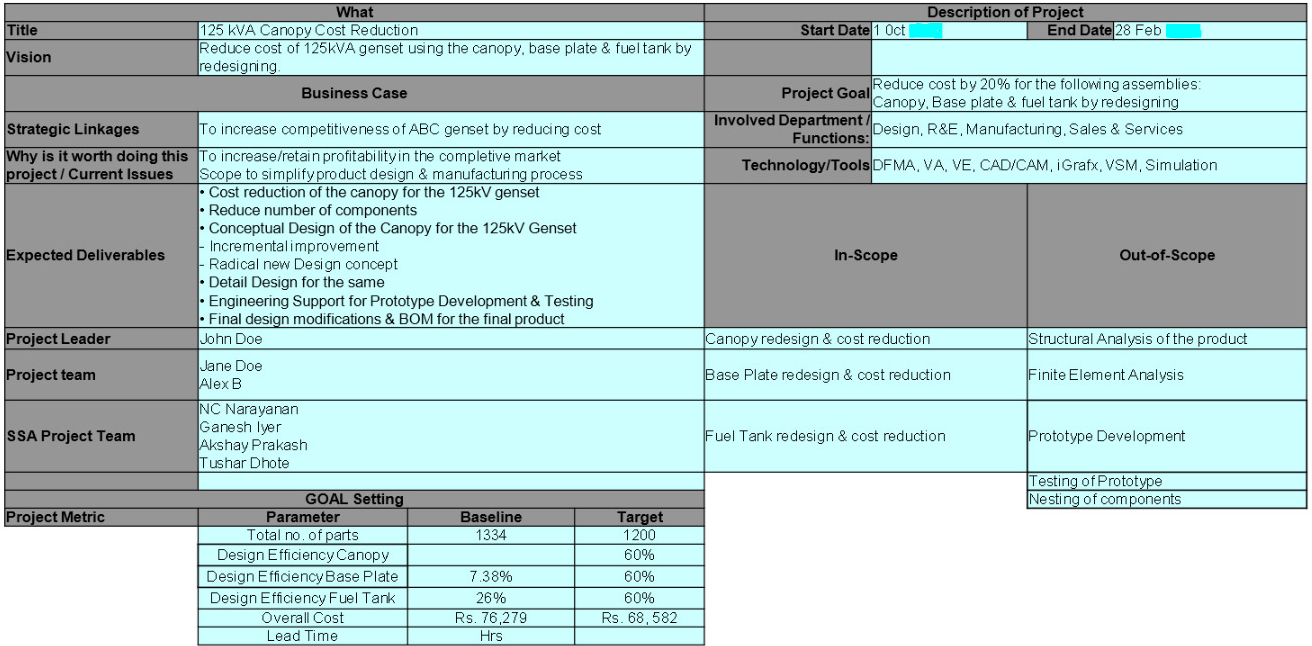

This project focused on product cost reduction for a Diesel Genset. The idea was to leverage value Engineering (VE) and Design For Manufacture Assembly (DFMA) concepts to achieve the desired outcome.

Action Taken

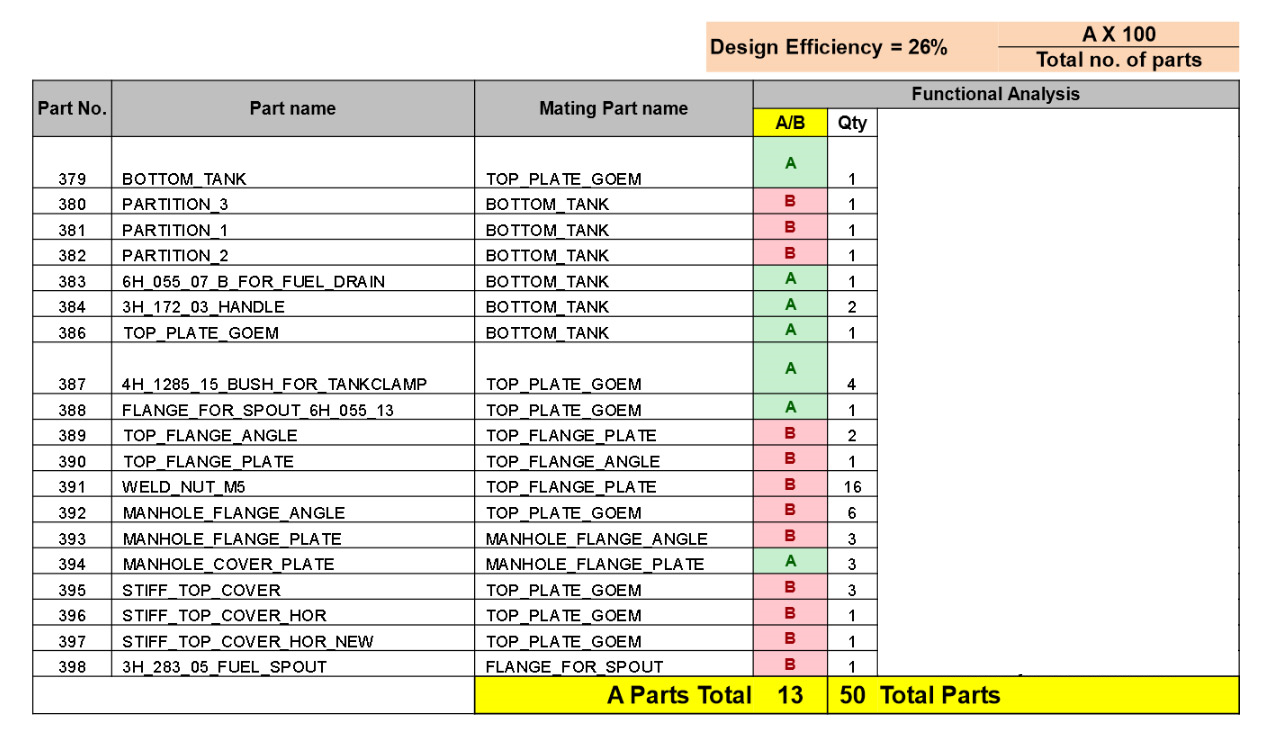

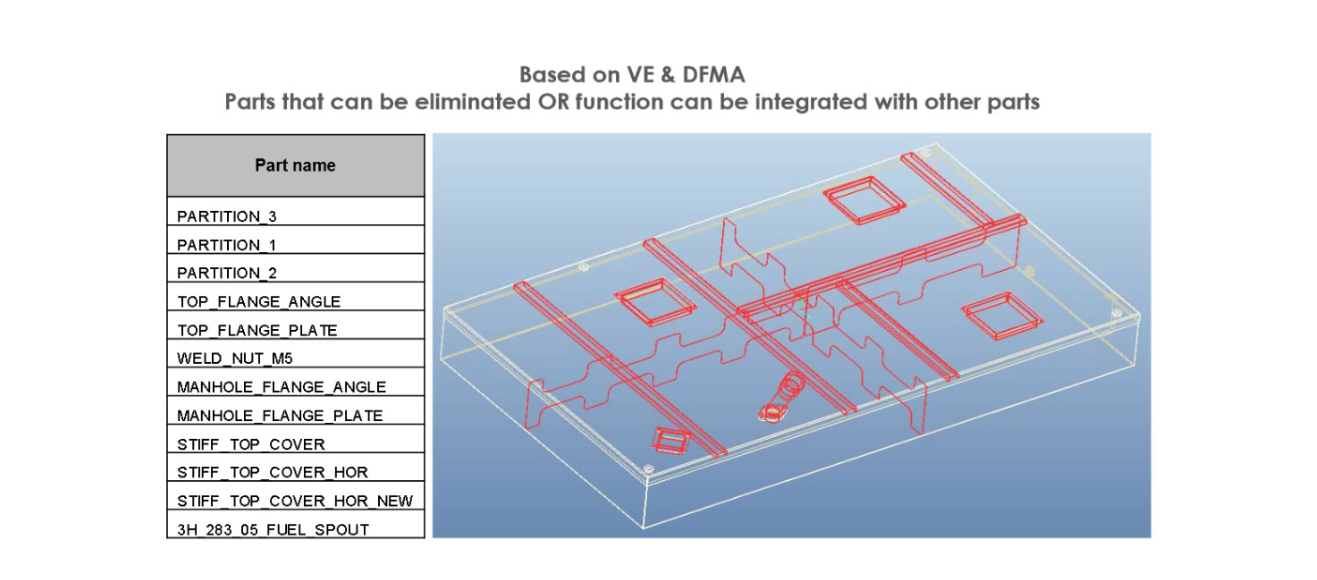

Detailed functional analysis was carried out and detailed design tear down study was undertaken with critical functional analysis. This revealed several opportunities to rationalize component count, as well as reduce overall product cost.

Results

Significant reduction in product cost, as well as design simplification was achieved in the process.

Situation – deep dive

This project focused on design optimisation of a genset canopy. The feedback from sales & marketing team was that they were losing out to competition due to high product cost. This project therefore focused on challenging the design choices in order to achieve reduce overall product cost.

Action Taken – deep dive

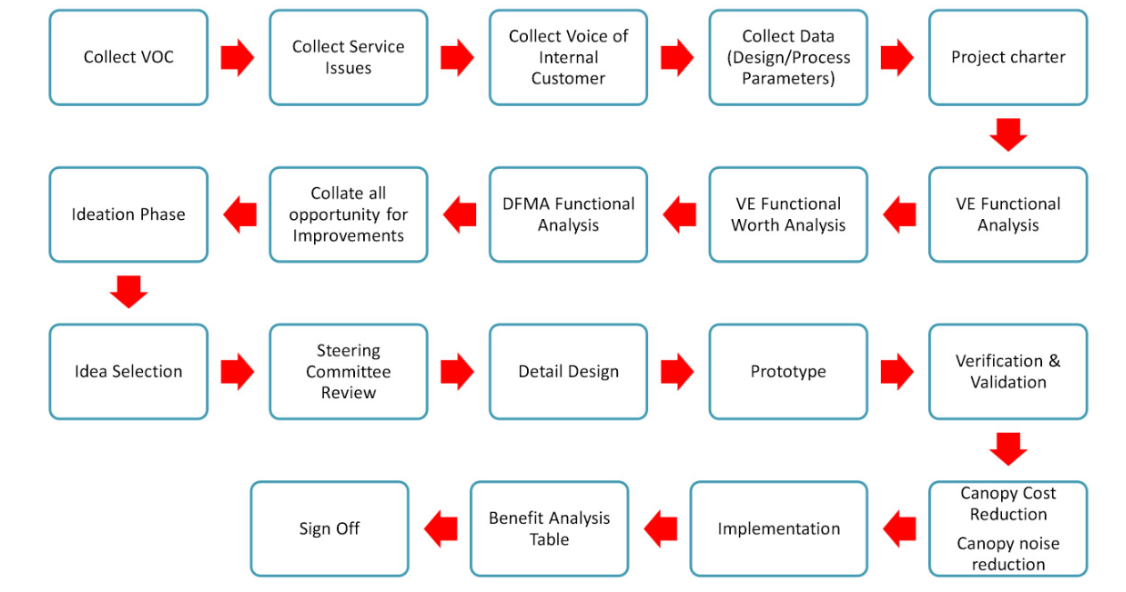

- VOC benchmarking and QFD performed to collate customer voice.

- Detailed tear down analysis.

- Value Engineering Functional Worth analysis.

- Cost/worth analysis.

- Components were classified into primary and secondary based on their functionality.

- New design concepts were explored based on VE/DFMA approach.

Actions Taken– deep dive

Actions Taken– deep dive

Actions Taken– deep dive

Actions Taken– deep dive

Results– deep dive

- Nearly 10% reduction in component count.

- Nearly 10% reduction in material cost.

- Improved design robustness.

- Skill development among designers.