News

Manpower Optimization for a Pharmaceutical Company

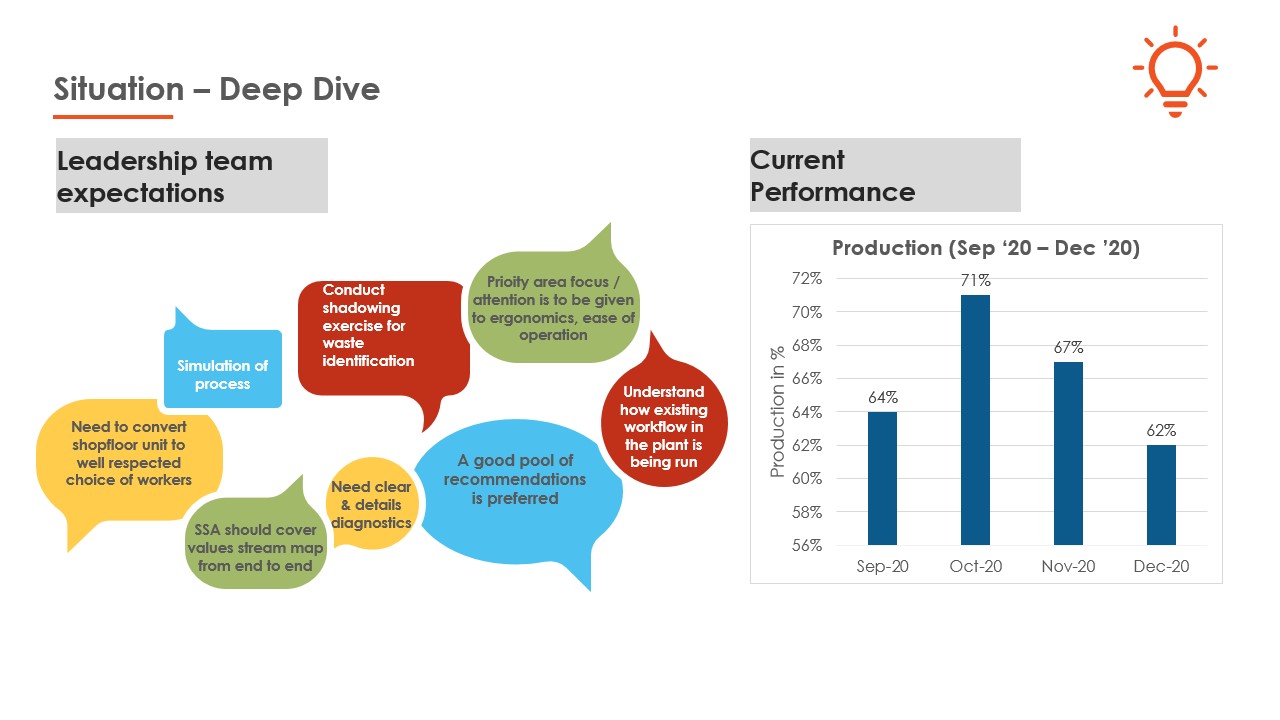

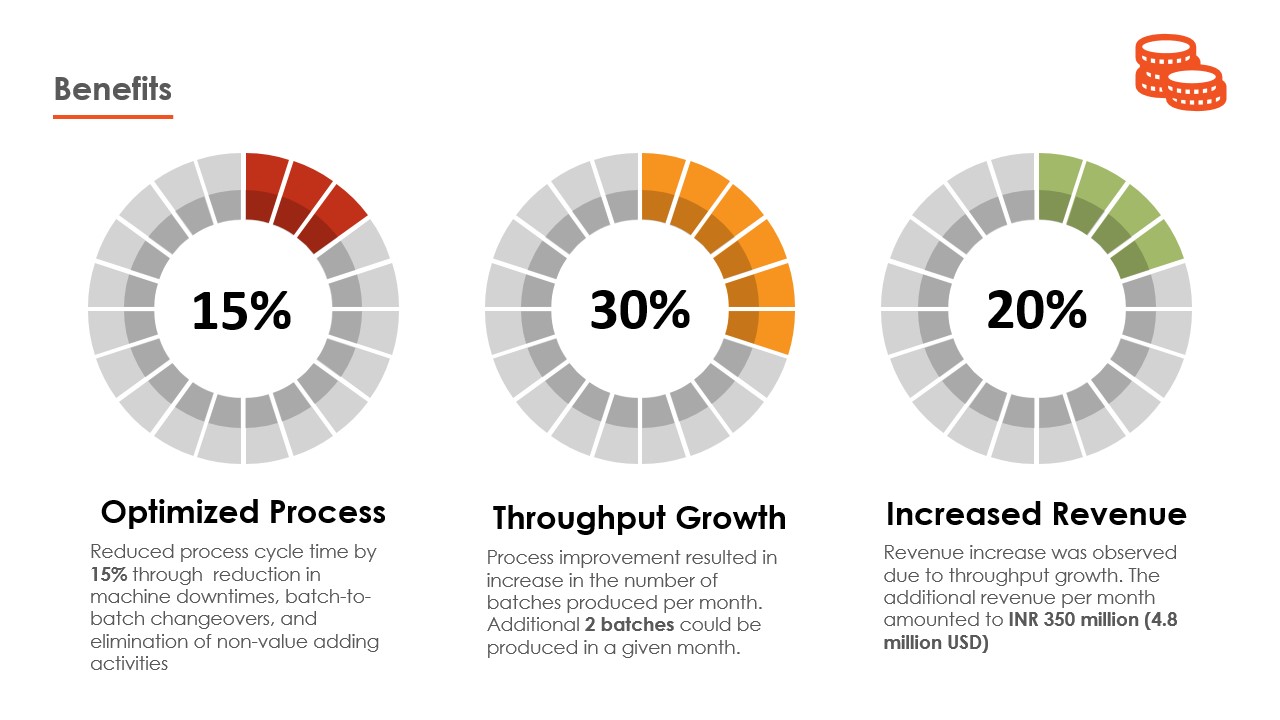

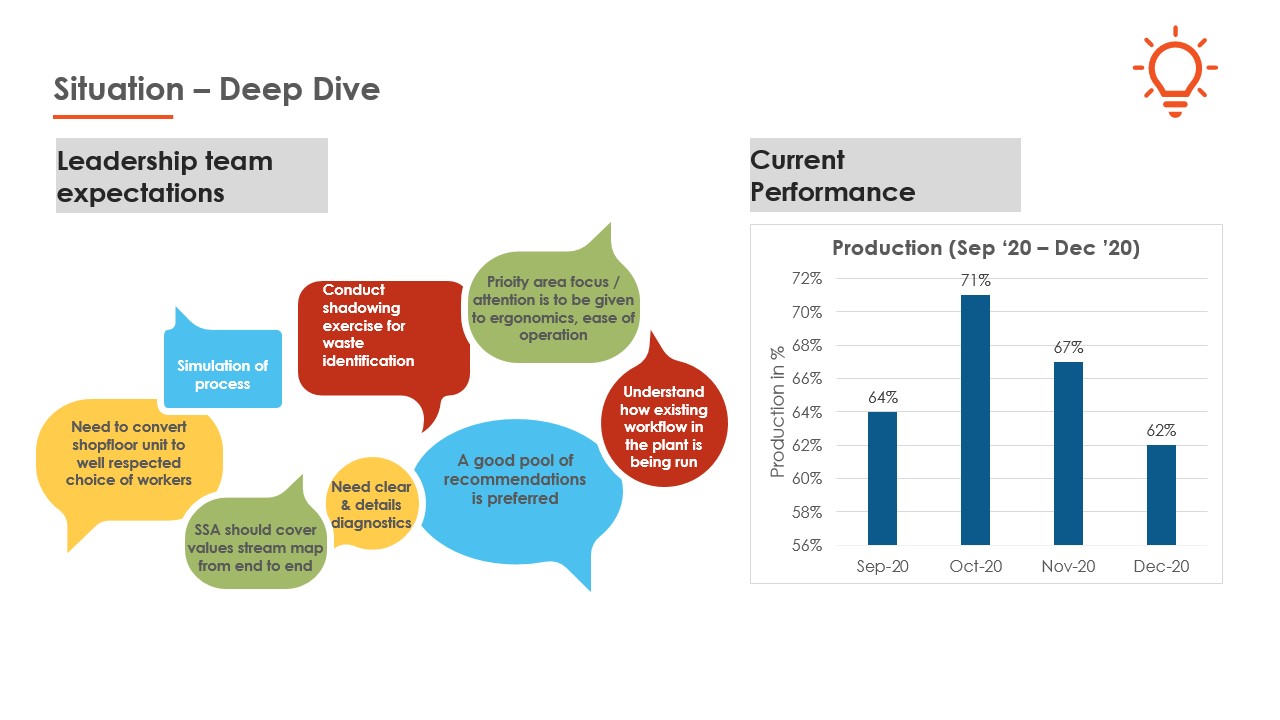

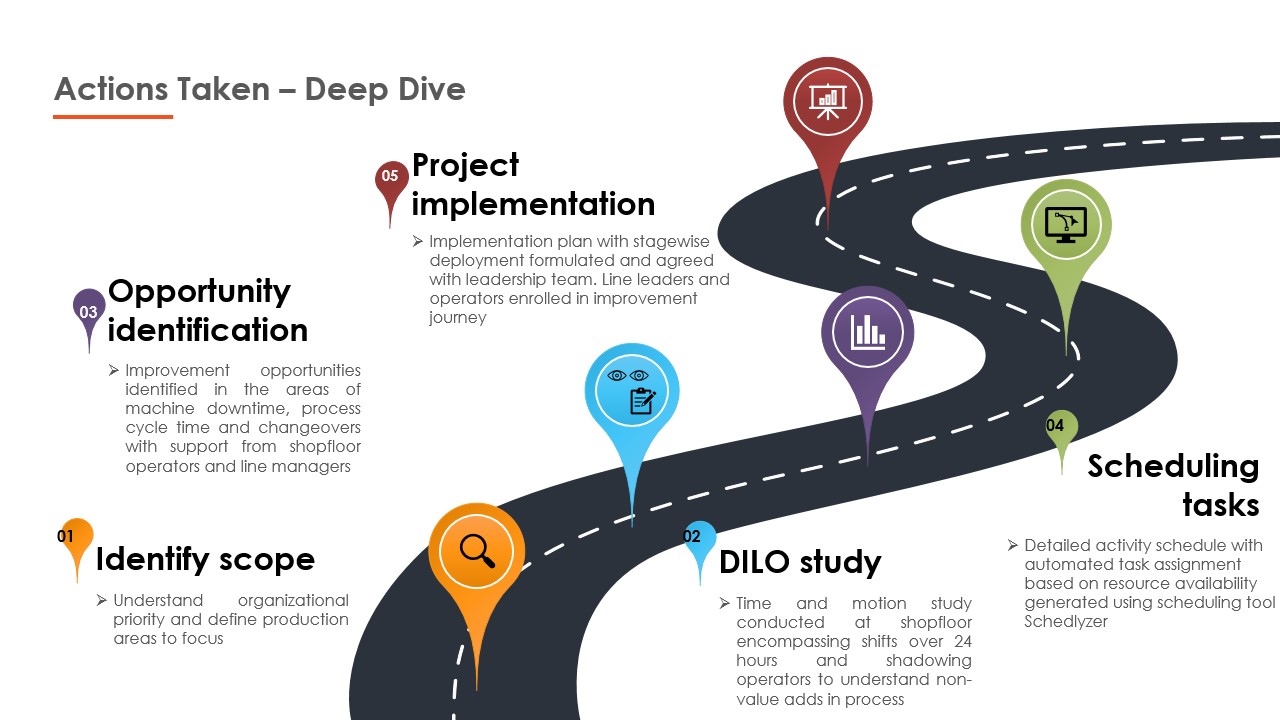

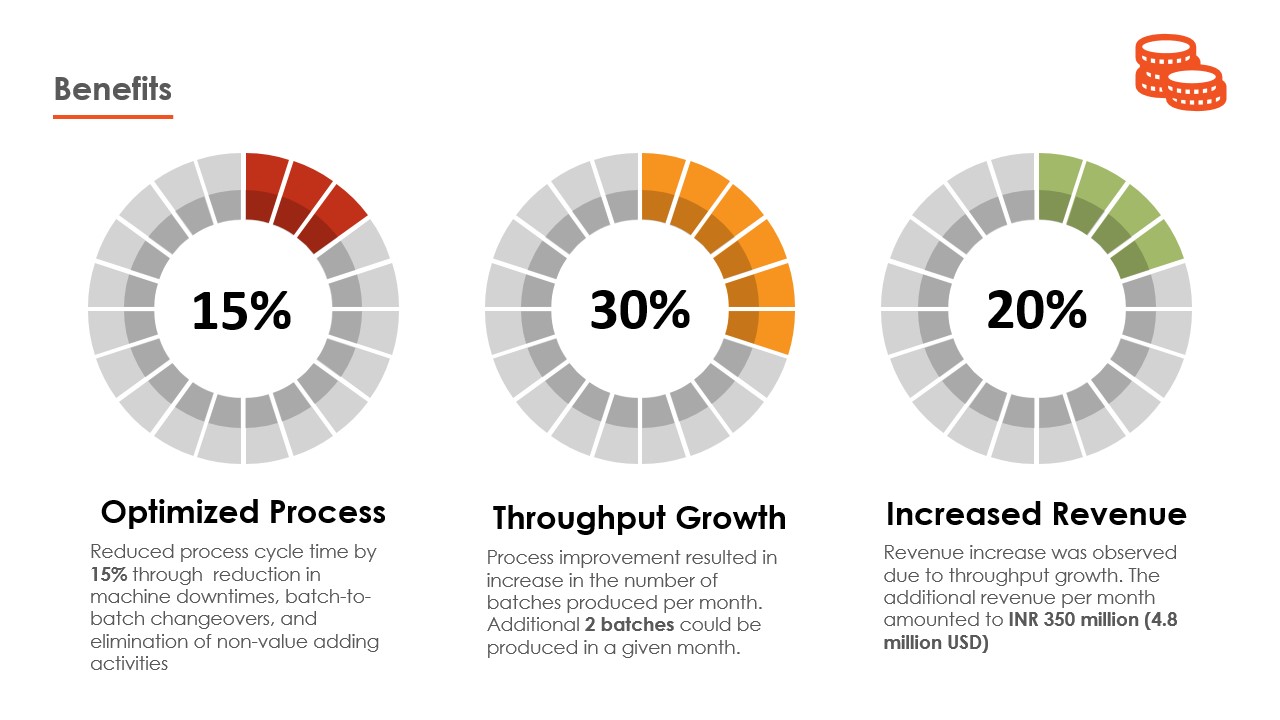

SSA Group of Companies helped a Pharma company to achieve an optimized manpower output for shopfloor operations. The result was achieved using a scheduler and analyzer tool named "Schedlyzer". The client company was challenged to meet the increasing product demand with the current production capacity and hence in their improvement journey partnered with SSA to help improve throughput.

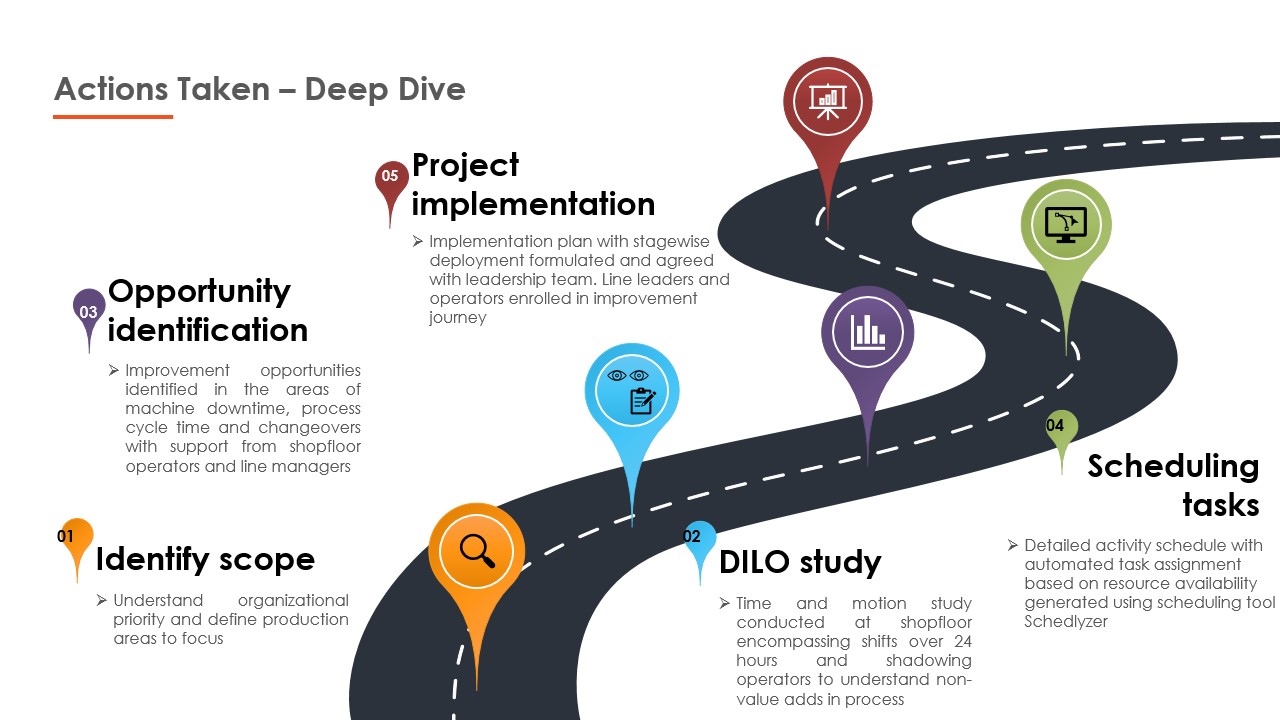

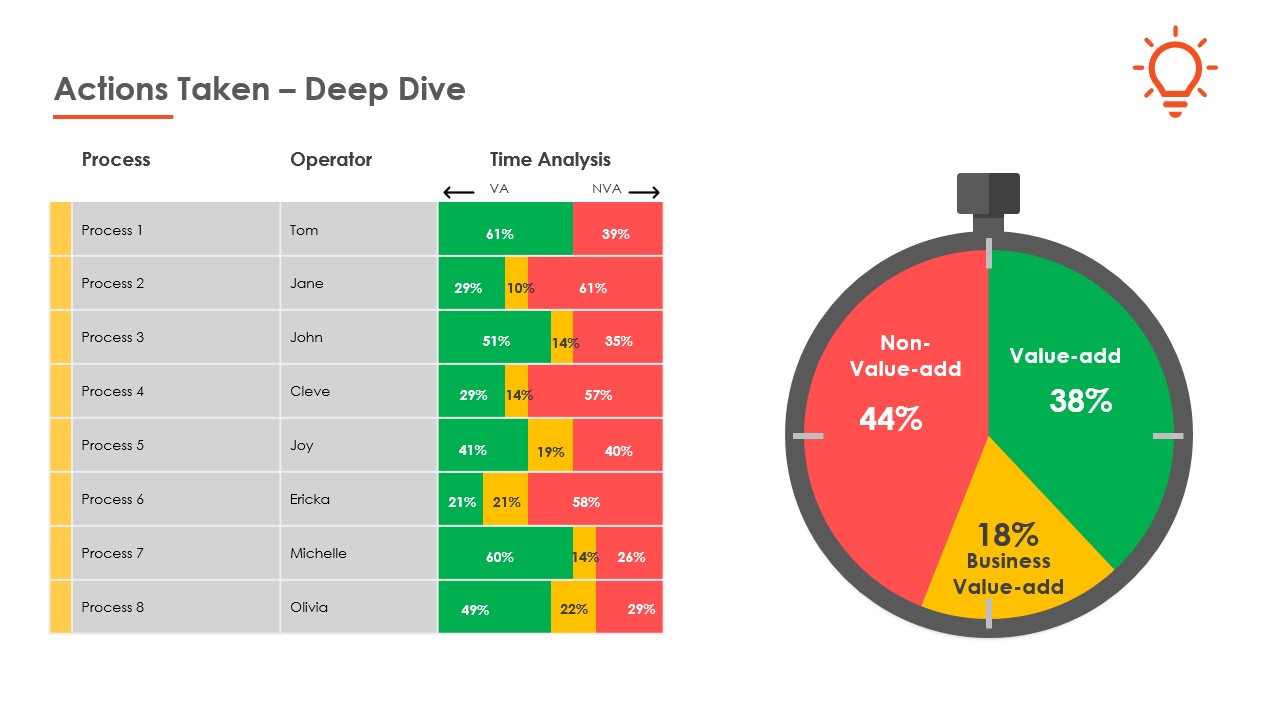

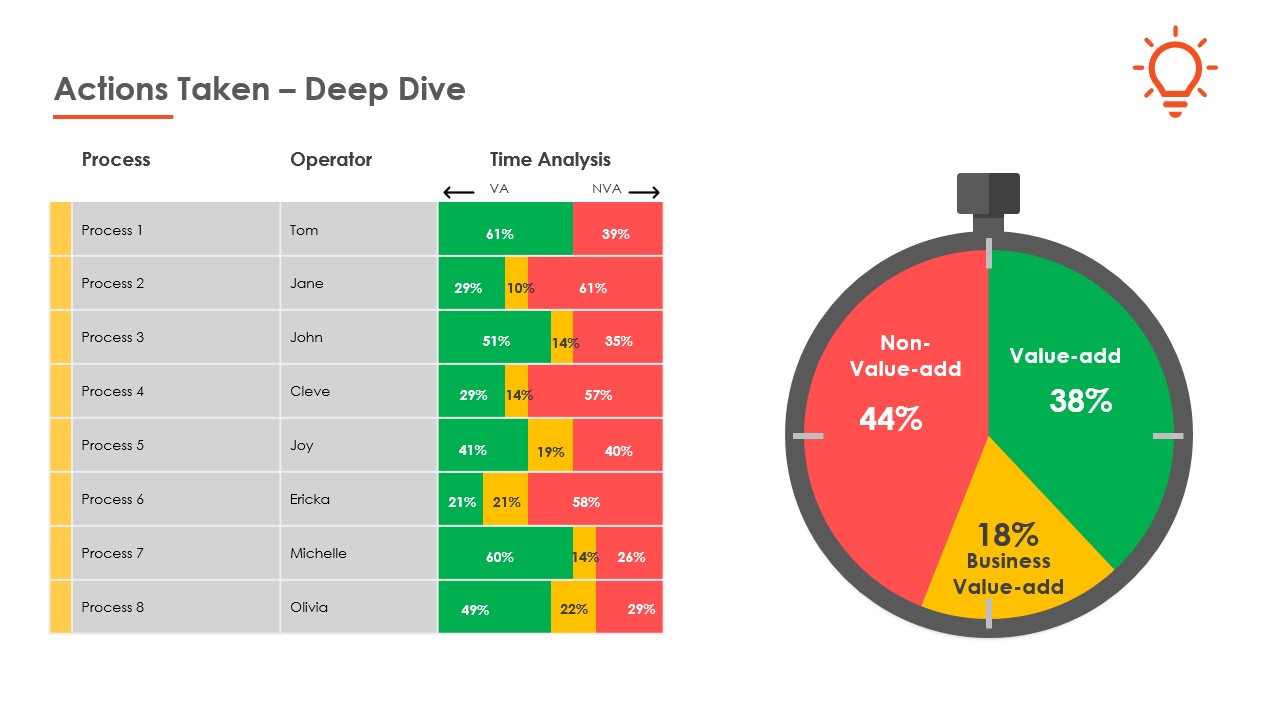

The SSA team with a colloborative approach with the Plant Team carried out an in-detailed DILO study, which helped them to gain a thorough understanding of the process and reduce the process cycle times using Lean initiatives.

In the present scenario, the shopfloor setup was able to produce only a handful of batches, due to lack of planning in scheduling the activities. Validation of new process was done using best-in class tool Schedlyzer which helped in scheduling the production and meet the demand.

With the help of "Schedlyzer", the client is now able to produce more batches in one month and with optimised manpower, meeting up with their expectations

The study was well appreciated by the Leadership team and also the operators on the shopfloor who now have a better visibility for the monthly activities to be performed in the form of a schedule!

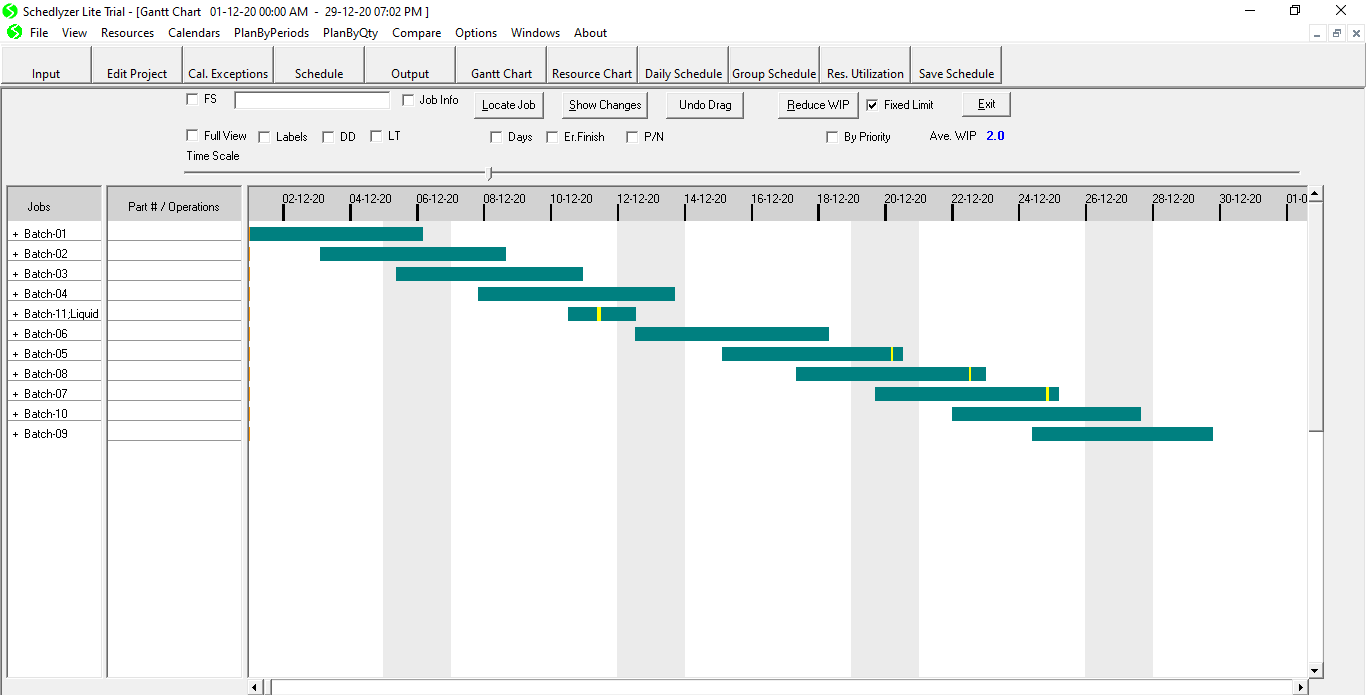

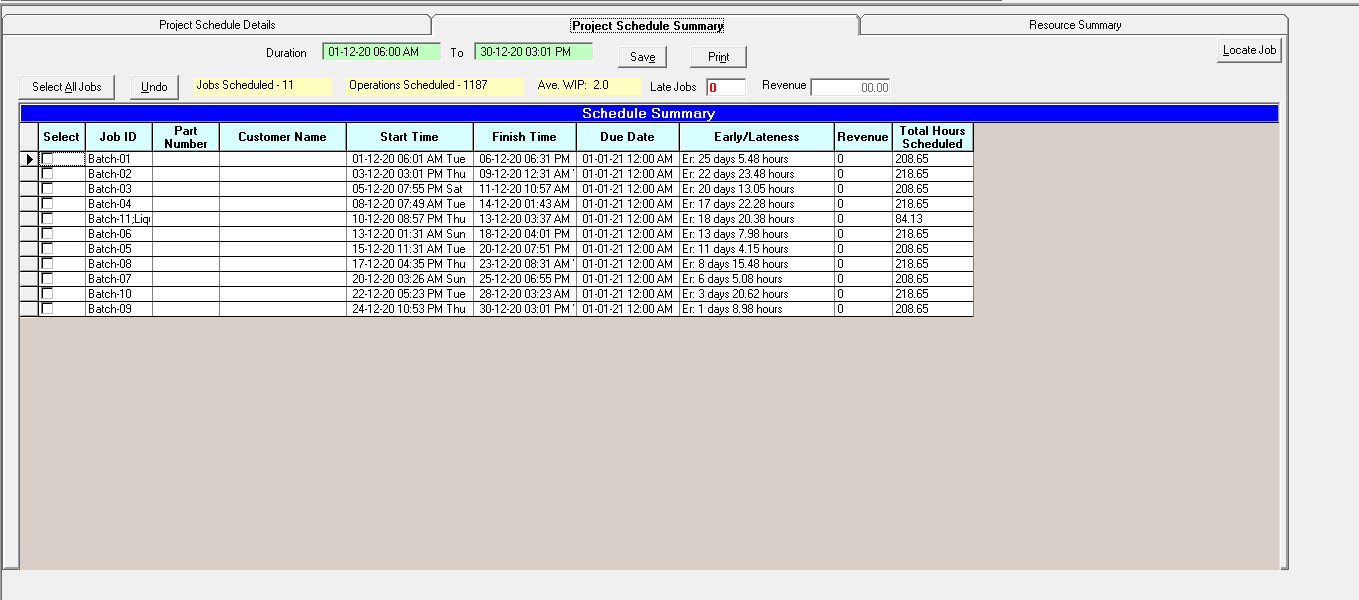

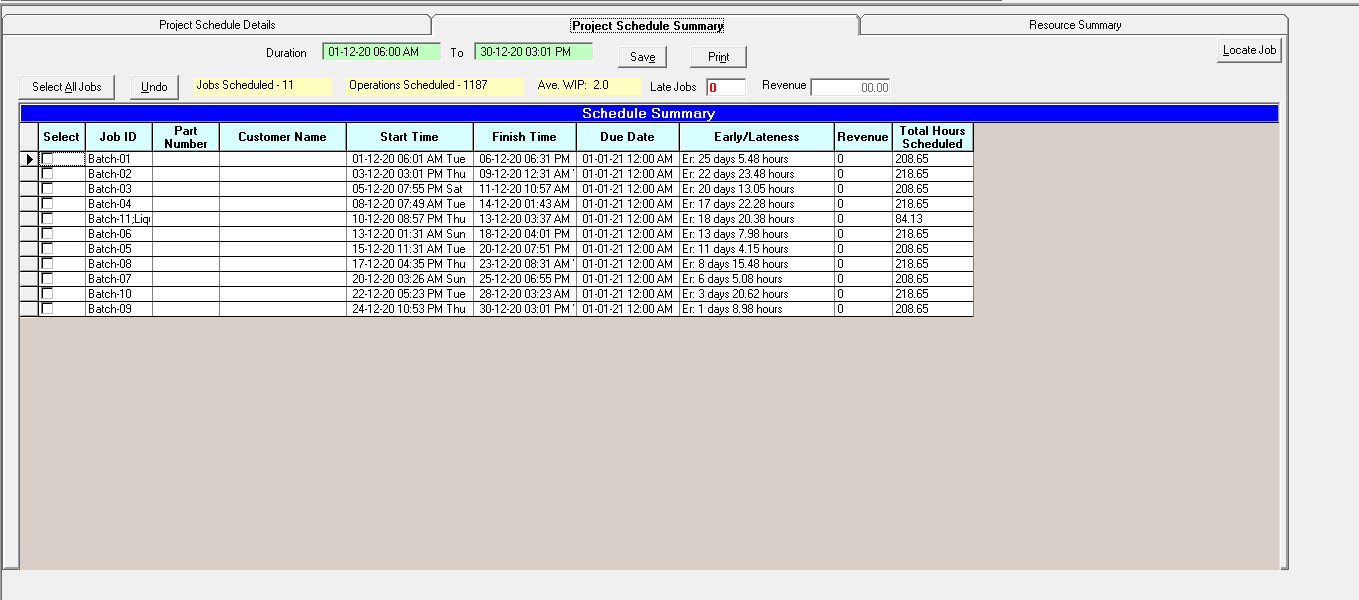

Schedule output from the tool

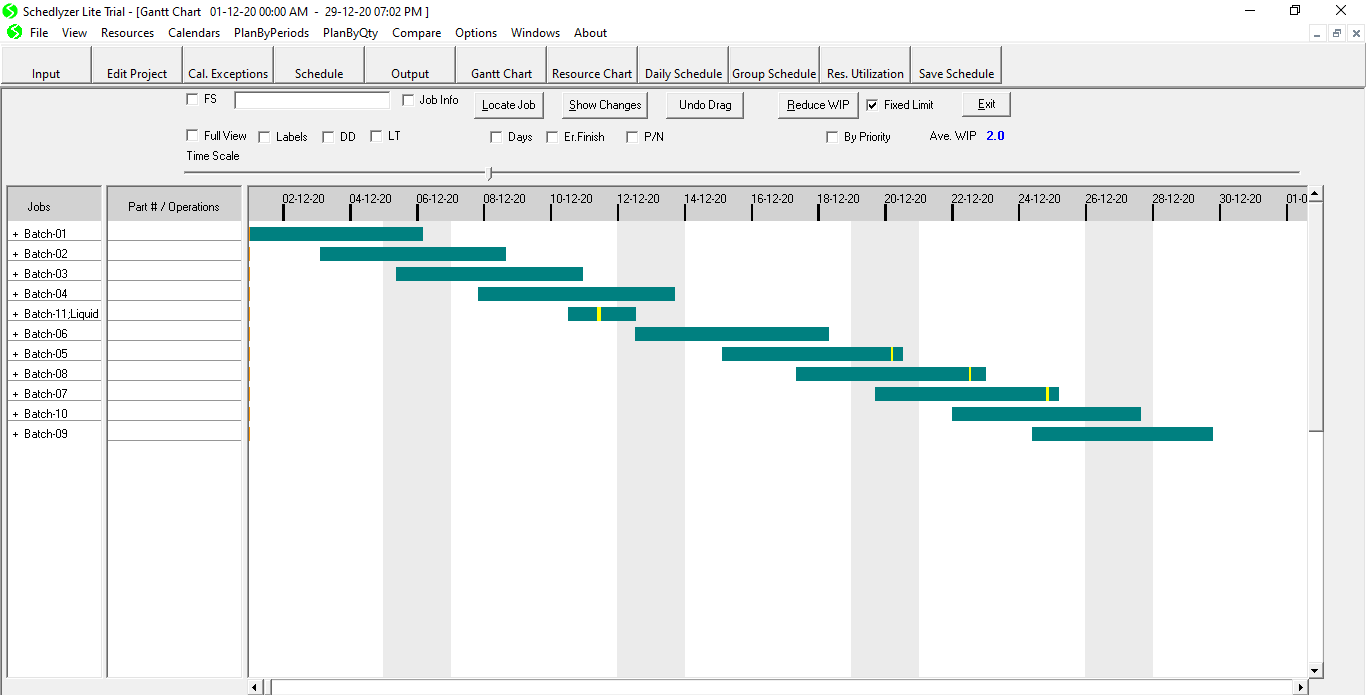

Gantt output

Manpower Optimization for a Pharmaceutical Company

SSA Group of Companies helped a Pharma company to achieve an optimized manpower output for shopfloor operations. The result was achieved using a scheduler and analyzer tool named "Schedlyzer". The client company was challenged to meet the increasing product demand with the current production capacity and hence in their improvement journey partnered with SSA to help improve throughput.

The SSA team with a colloborative approach with the Plant Team carried out an in-detailed DILO study, which helped them to gain a thorough understanding of the process and reduce the process cycle times using Lean initiatives.

In the present scenario, the shopfloor setup was able to produce only a handful of batches, due to lack of planning in scheduling the activities. Validation of new process was done using best-in class tool Schedlyzer which helped in scheduling the production and meet the demand.

With the help of "Schedlyzer", the client is now able to produce more batches in one month and with optimised manpower, meeting up with their expectations

The study was well appreciated by the Leadership team and also the operators on the shopfloor who now have a better visibility for the monthly activities to be performed in the form of a schedule!

Schedule output from the tool

Gantt output